PalmFil is the world’s first textile fibers and reinforcements extracted from the byproducts of pruning of date palms, such as the frond and fruit stalks.

PalmFil creates value out of the large quantities of underutilized byproducts of the 140 million date palms (FAO), which are otherwise open field burned!

It expands the palette of natural fibers and increases the biodiversity of fiber crops. Resulting in larger, more sustainable, and economical supply, which supports and encourages the industrial shift back to natural fibers.

Frond stalks

Fruit stalks

PamFil is very versatile and can be processed into many textile forms, including, long fiber tows, chopped fibers, spun yarns/ rovings, nonwoven mats, woven fabrics, unidirectional tapes, pre-impregnated, comingled and finely milled fibers.

Tow

Chopped

Yarn

Nonwoven

Woven

Composite

The unique features and characteristics of PalmFil make it an excellent sustainable material base for a wide spectrum of industries. Ranging from natural reinforcements for composites in automotive and sporting goods, plaster reinforcements in construction, burlap sacks for packaging, ropes, and twines, non-wood papers, and other consumer products.

Automotive

Construction

Sporting

Packaging

Ropes

Non wood Paper

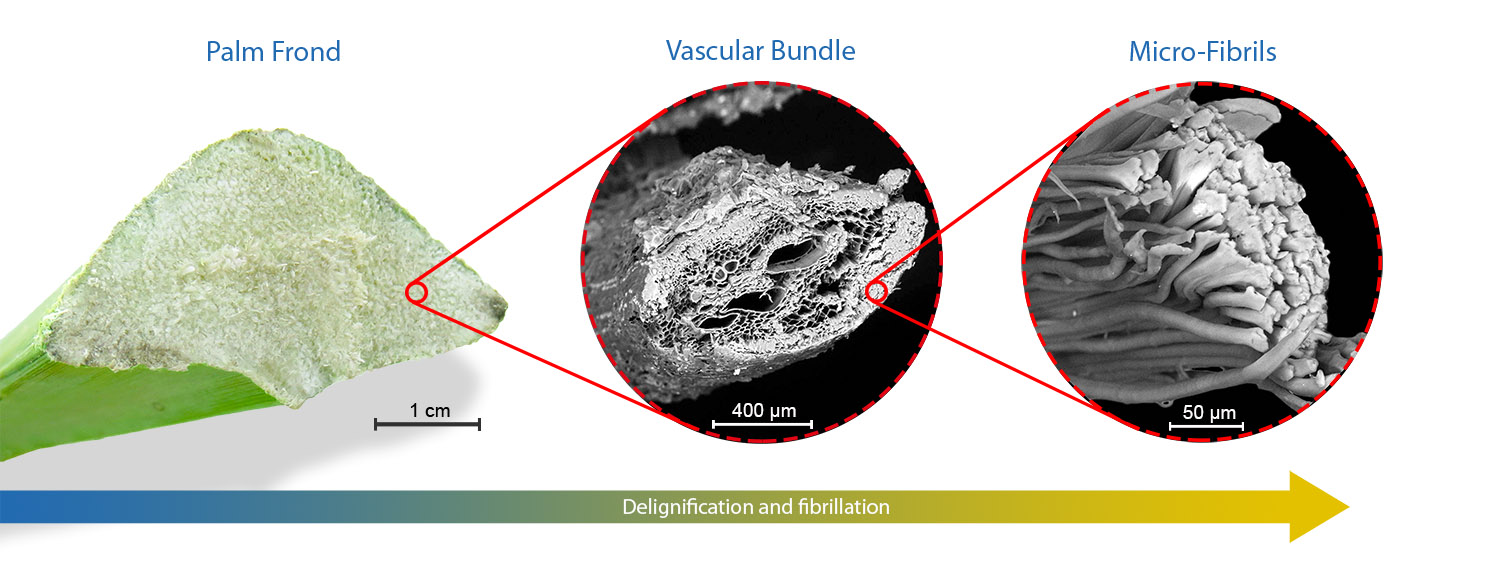

PalmFil is based on a proprietary technology for extracting long pure textile fibers from the date palm byproducts such as the frond and fruit stalks. The process delignifies and fibrillates the vascular bundles and eliminates the hollow lumens without causing any damage or breakage to the fibrils.

The novel PalmFil fiber was well received by the scientific community. It was featured in research and review articles in some of the most prestigious scientific journals in the field, such as, Industrial Crops and Products (Elsevier) and Cellulose (Springer).

PalmFil was also well accepted by the industrial community in Egypt, and it has been processed on a full industrial scale spinning line at the Egyptian Industrial Center of Flax. It was also of high interest to one of the largest sisal and abaca spinning companies in the Middle East, Canal Rope Company an affiliate of the Suez Canal Authority in Egypt.

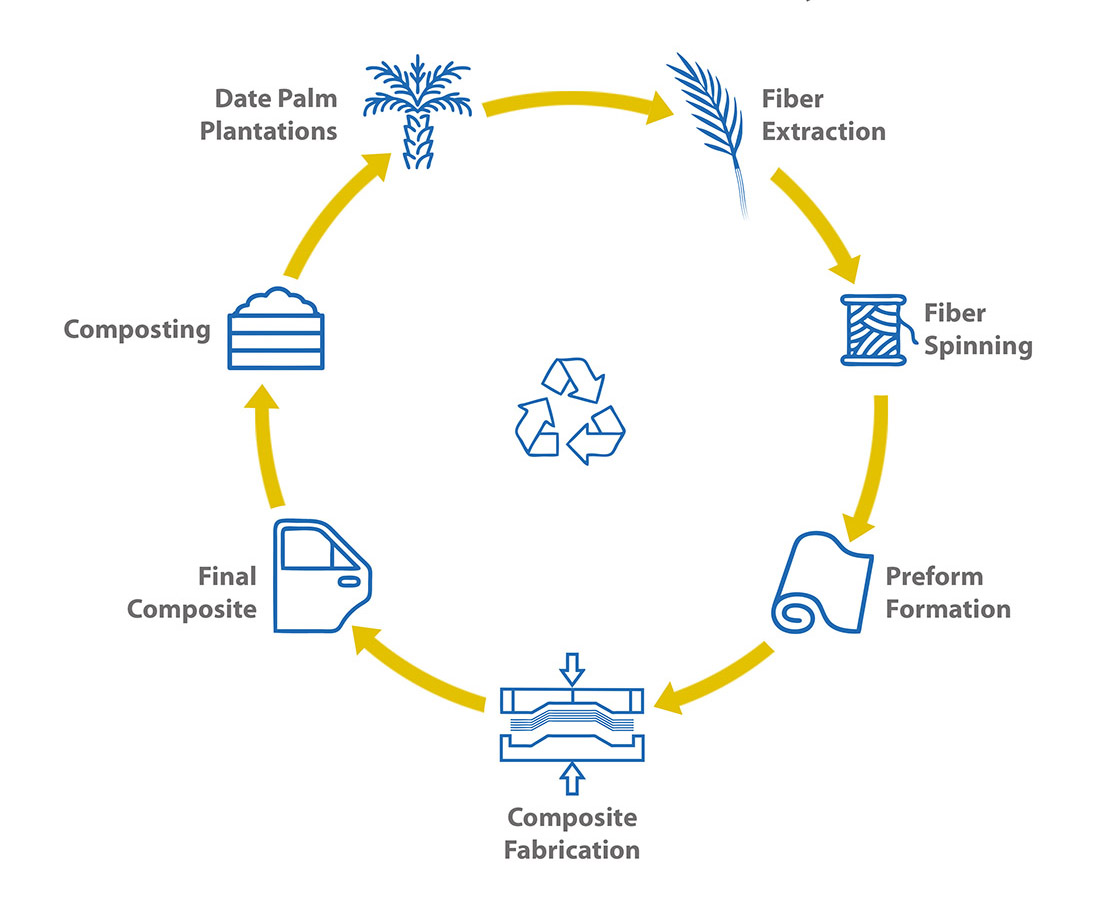

PalmFil contributes to the circular bioeconomy following a closed loop cycle from cradle to cradle. Palmfil extraction technology could be applied to byproducts of other palm species such as oil palm, sugar palm, doum palm as well as other agriculture byproducts such as broomcorn.

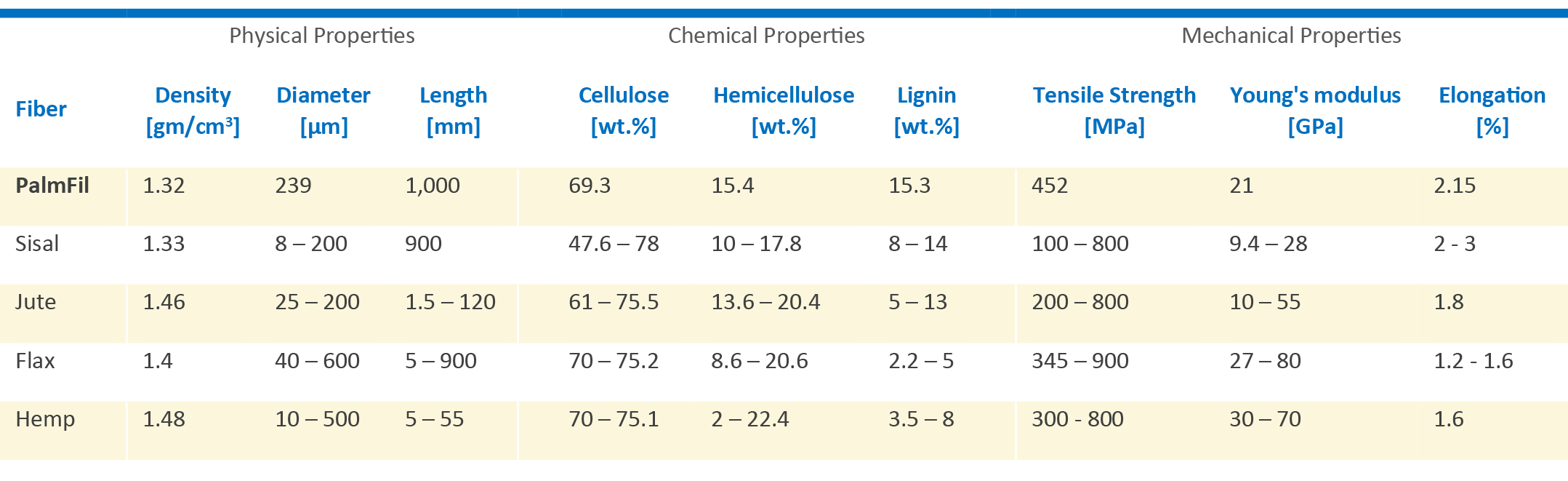

Comparison of PalmFil properties with other vegetable fibers

Palmfil is developed by VALORIZEN Research and Innovation Center which is specialized in developing, scaling up and commercializing technologies to valorize sustainable materials. It is the research arm and a wholly owned subsidiary of UK-based Scaleup Innovations Holdings Limited. VALORIZEN operates in 3 core areas, including biomass valorization, waste valorization, as well as knowledge valorization.

Mohamad Midani Ph.D.

Managing Partner – Intexive

Asst Prof – Materials Engineering,

German University in Cairo

Ahmed Hassanin Ph.D.

Partner – Intexive

Assoc Prof – Textile Engineering,

Alexandria University

Tamer Hamouda Ph.D.

Partner – Intexive

Sr Researcher – Textile Division,

National Research Center

Lobna Elseify

Lecturer Asst & PhD student –

Materials Engineering,

German University in Cairo

Yomna Sherif

Lecturer Asst & MSc student –

Materials Engineering,

German University in Cairo

We believe that there is a very promising future for PalmFil as a novel class of natural textile fiber, with an estimated annual market worth of US$ 2.5 billion. We are seeking partnership to further develop, scale-up, and commercialize PalmFil fiber technology. The scope of partnership includes but is not limited to;

- Licensing/ technology transfer

- Support further development

- Sponsor building a pilot production unit

Possible partners include automotive companies, OEMs of fiber extraction and spinning lines, developmental organizations, government agencies, and research funding organizations.

Contact us

For inquiries, collaboration, partnership, sponsorship, and trial samples,

Contact Dr. Said Awad

VALORIZEN R&I Center, Cairo, Egypt